Hydrogen – the key to a CO2-neutral economy

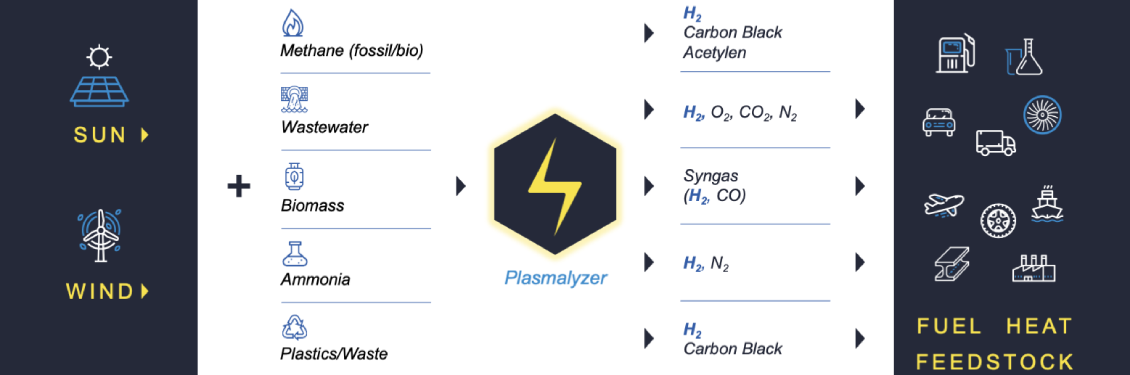

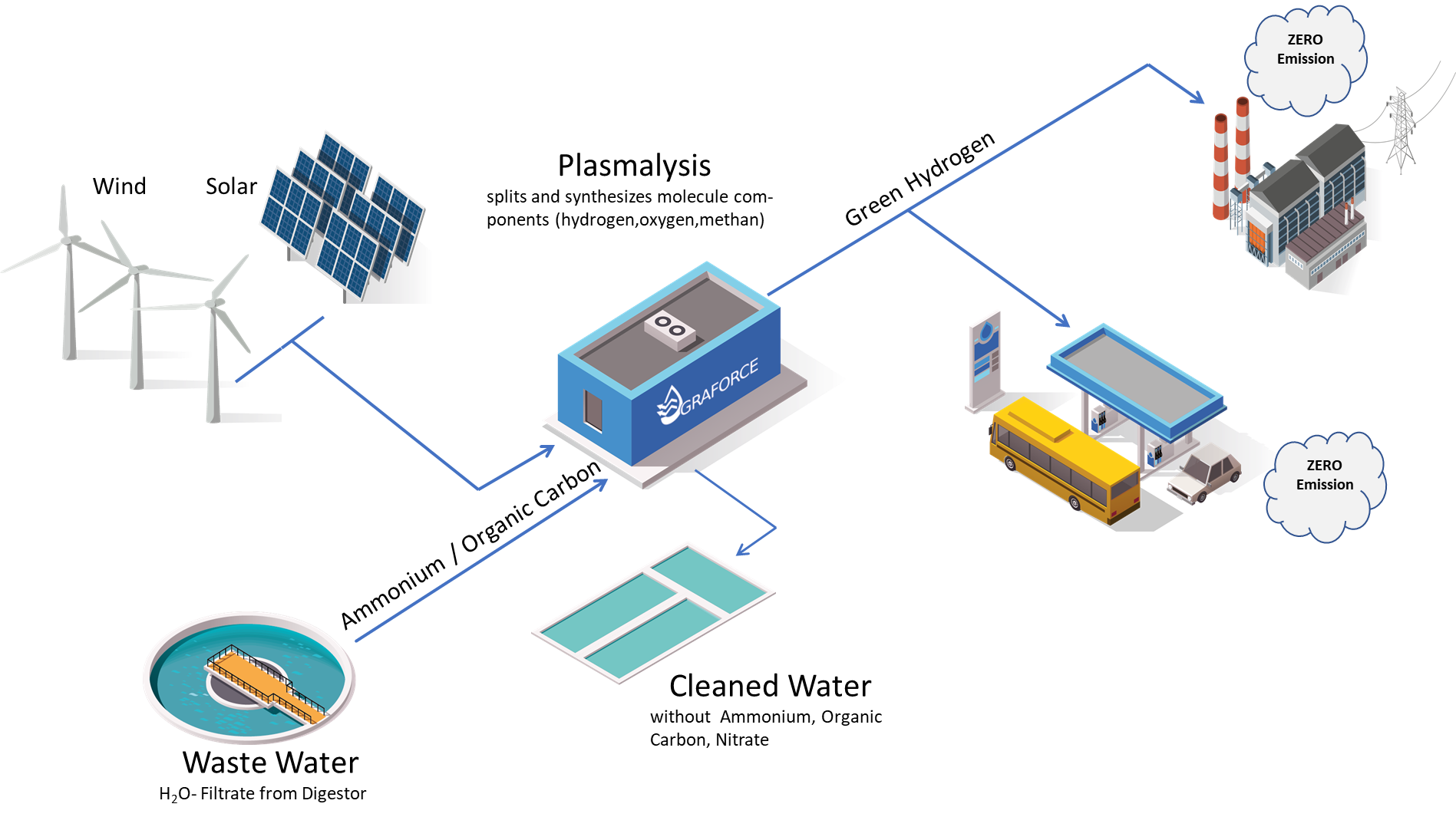

Hydrogen holds enormous energy potential and is not only found in water. It is a component of many organic and inorganic compounds in industrial wastewater, slurry, ammonia and gases. Graforce offers plasma electrolyzers known as Plasmalyzers® that produce hydrogen from high-energy chemical compounds in residual materials – with significantly lower manufacturing costs and higher yields.

Hydrogen is more tightly bound in water than in other chemical compounds such as methane or ammonia. For this reason, the Methane Plasmalyzers® require much less energy than previous electrolysis processes. Costs drop from an average of 6 to 8 euros to only 1.5 to 3 euros per kg of hydrogen.

The marketable, modular systems enable the production of CO2-free and CO2-negative hydrogen, thus making a significant contribution to the decarbonization of the economy.

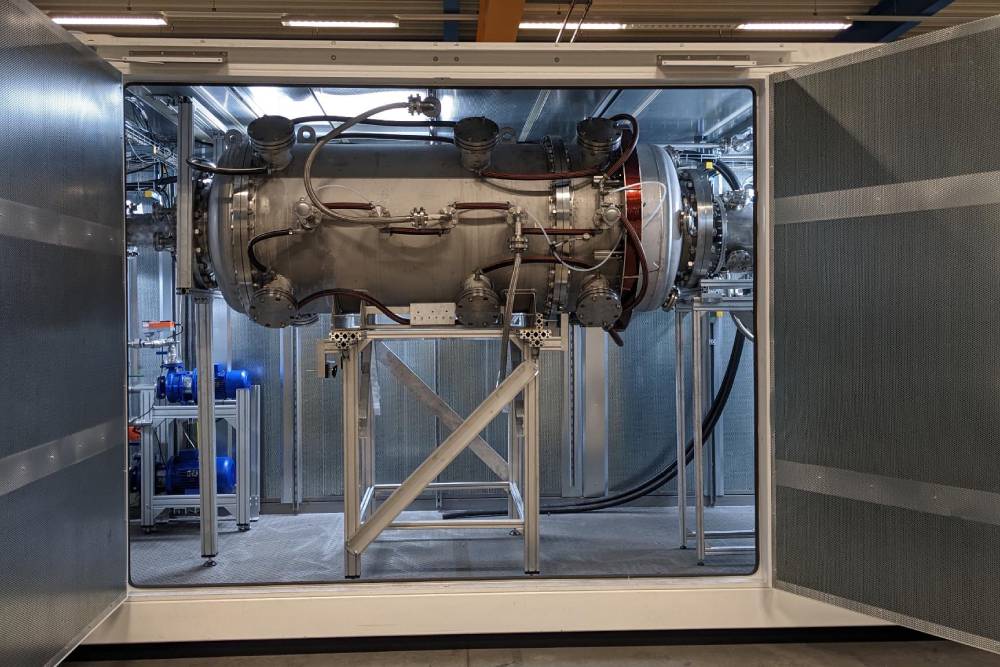

Graforce has successfully built and commissioned a methane electrolysis plant at RAG Austria AG. Around 50 kg of hydrogen and 150 kg of solid carbon are produced from 200 kg of natural gas or biomethane per hour.

The plant comprises two containers with three 200kW plasmalyzer modules, a filter for separating hydrogen and solid carbon, a carbon filling plant and an H2 compressor with storage bank for the H2 CHP.

The hydrogen can be used for emission-free electricity and heat generation or stored underground. High-purity carbon is a valuable raw material for various industrial applications (steel, concrete, asphalt, electrodes or soil improvement). As the CO2 is bound in products in the long term, this technology is also the first market-ready alternative to carbon capture storage.

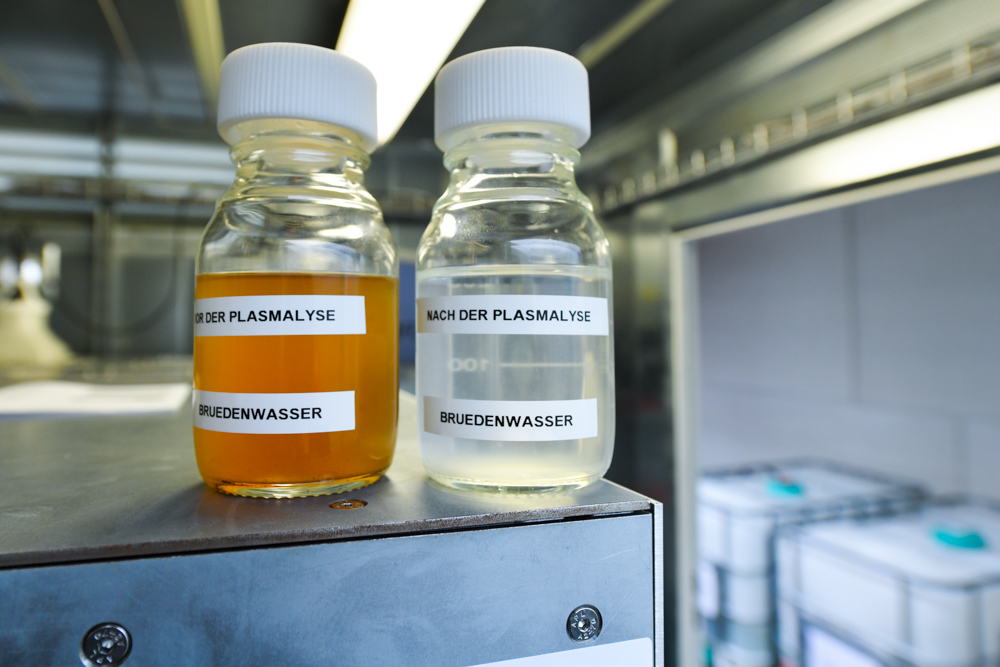

Turning residual materials into recyclables

Green hydrogen from residual materials significantly contributes to the circular economy and can reduce CO2 in the atmosphere when used with biogas. Graforce thus offers a marketable alternative to the controversial storage of CO2 (Carbon Capture Storage).