Steel and other industries

Hydrogen-Based Direct Reduction (H₂-DRI): The Key to Decarbonizing Steel Production

Hydrogen-based direct reduction (H₂-DRI) is considered a crucial lever for decarbonizing the steel industry. However, green hydrogen often lacks cost-effectiveness and availability — especially in the volumes required for industrial high-temperature processes. This is where methane plasmalysis comes in: an innovative process that produces hydrogen from natural gas or biomethane without CO₂ emissions — and with valuable by-products.

CO₂-Free Hydrogen Production — with Integrated Carbon Utilization

In methane plasmalysis, methane (CH₄) is split into hydrogen (H₂) and solid carbon (C) in a high-temperature plasma process — completely without generating CO₂. For every kilogram of hydrogen produced, approximately 3 kg of solid carbon is generated, which can be used as a high-value raw material in foundries or metallurgy.

High-Temperature Waste Heat — Utilized in Steelmaking

A key advantage: the process generates high-temperature waste heat of up to 750 °C, which can be used directly as process steam in the direct reduction process. This replaces fossil energy typically used for heating hydrogen — and significantly reduces CO₂ emissions.

Triple Benefit for Industry:

- Green hydrogen for direct reduction — CO₂-free and cost-efficient

- Solid carbon as a metallurgical additive — a profitable secondary raw material

- High-temperature process heat — directly usable in existing industrial plants

Future-Ready Steel Production Starts with a Flexible Energy Carrier

Methane plasmalysis works with fossil natural gas, biogenic methane, or flare gas — offering a highly scalable transitional technology for decarbonizing the steel industry. When powered by biomethane, the hydrogen produced can even achieve negative carbon intensity.

Low-Carbon Hydrogen for the Steel Industry — Cost-Effective and Scalable

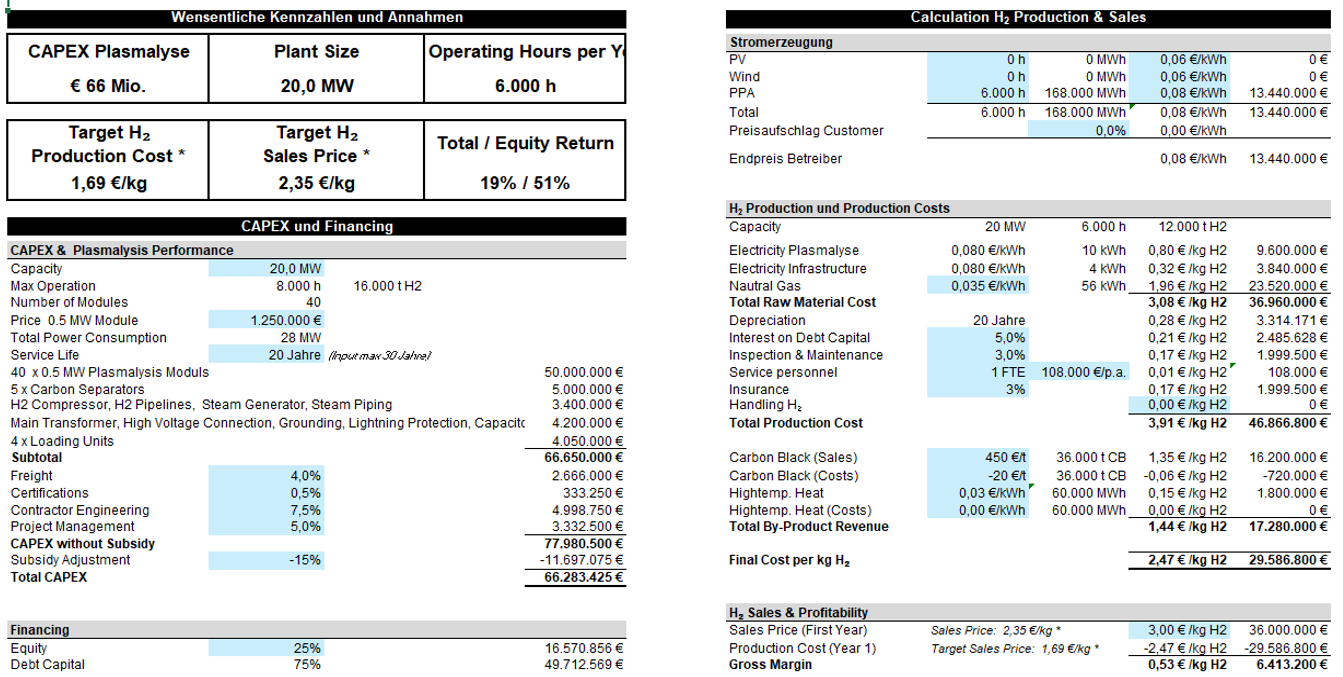

Methane plasmalysis not only delivers low-carbon hydrogen but also reduces production costs well below current market levels. A recent business case analysis shows: the integration of a 20 MW methane plasmalysis system (40 modules à 0.5 MW) into a German steel plant drastically cuts CO₂ emissions — while delivering clear economic benefits.

Key Results at a Glance

🔹 Production Capacity & Operating Hours

The plant operates 6,000 hours per year, producing 12,000 tons of hydrogen annually — CO₂-free, reliable, and scalable.

🔹 Hydrogen Production Cost

Hydrogen is produced at a cost of €2.47/kg, significantly below current market prices for green hydrogen.

In the long term, costs can drop to €1.69/kg.

🔹 Energy & Feedstock Costs

Per kilogram of hydrogen, the plasmalysis process requires:

- 10 kWh electricity for plasma generation

- 4 kWh electricity for infrastructure

- 56 kWh natural gas (e.g., biomethane or fossil gas)

Energy prices (Germany, PPA & gas market):

- Electricity: €0.08/kWh (via Power Purchase Agreement)

- Natural gas: €0.035/kWh

→ Total energy & gas cost: €3.08/kg H₂

🔹 Byproduct Utilization

- Solid carbon (450 €/t) is sold to foundries

- High-temperature waste heat (750 °C) is directly reused in the DRI steelmaking process

→ This saves €1.44/kg H₂ through byproduct value recovery

🔹 Sales Price & Margin

At a target sales price of €2.35/kg H₂, the project achieves an attractive gross margin of €0.53/kg, or €6.4 million profit per year

🔹 CAPEX & Economic Viability

- Total CAPEX: €66 million (including infrastructure, storage, separators, etc.)

- Equity Return: 51%

- Total Return on Capital: 19%

Energy recovery from process water

Industrial processes generate various types of waste products. These usually must be processed or collected and disposed of at great expense. With the help of wastewater plasmalysis a high share of the nitrogen and carbon compounds it contains can be converted into valuable industrial gases such as hydrogen, nitrogen, methane and oxygen.

The hydrogen can be used directly for CO2-free heat and power generation in hydrogen CHP units or SOFC fuel cells. The solid carbon is a valuable auxiliary material for industry and is used for asphalt, concrete, cement or soil improvement, for example. This enables long-term removal of CO2 from the cycle and is therefore exempt from the CO2 tax.

Would you like to learn more about the many possible applications of plasmalysis in industry? We would be happy to advise you on individual adaptations.