Energy management

Graforce offers marketable, modular Plasmalyzer® systems to biogas plant operators and the oil and gas industry to produce CO2-free or CO2-negative hydrogen – and an economical solution to meet climate goals.

Graforce offers marketable, modular Plasmalyzer® systems to biogas plant operators and the oil and gas industry to produce CO2-free or CO2-negative hydrogen – and an economical solution to meet climate goals.

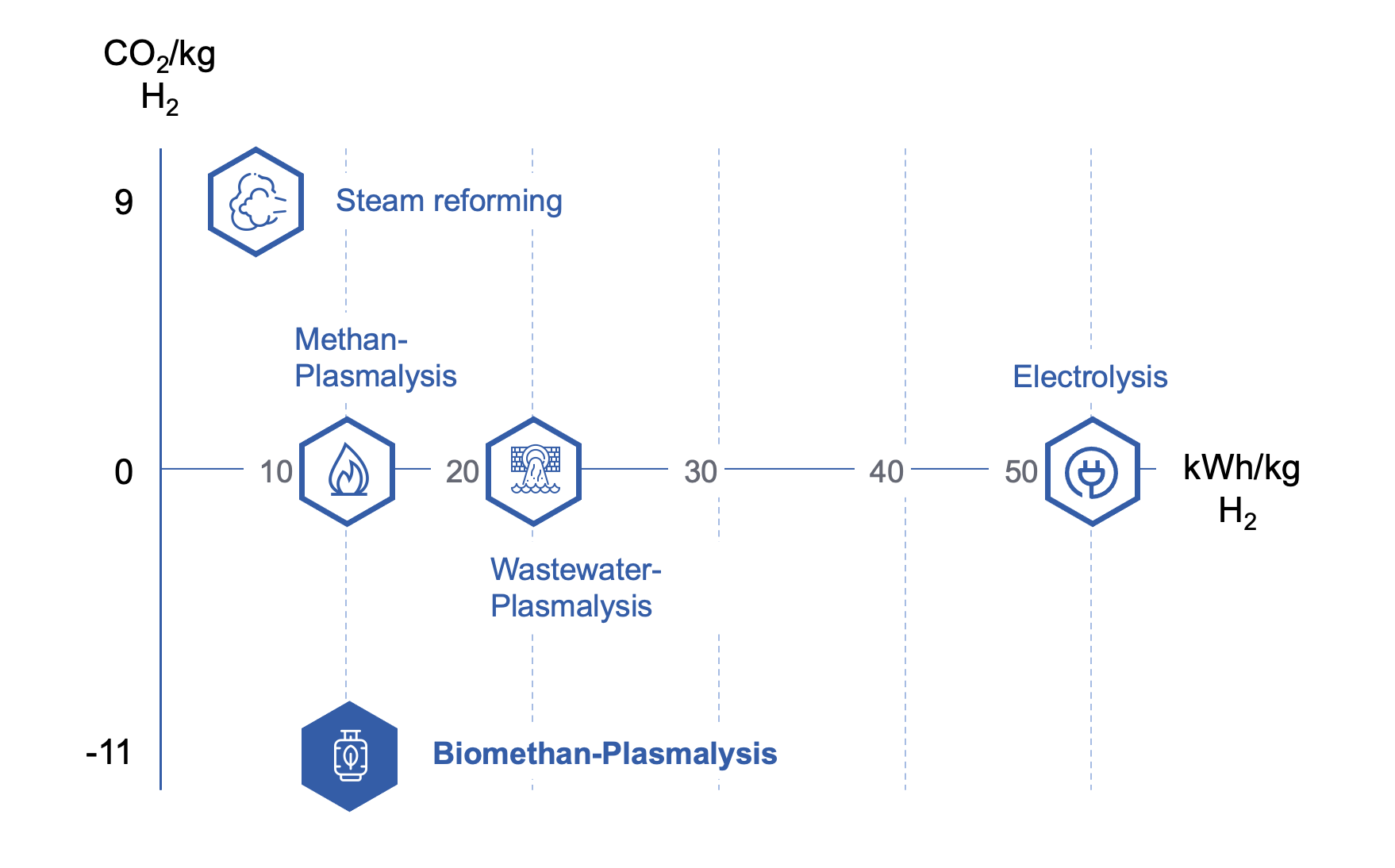

The Methane Plasmalyzer® produces hydrogen (10kWh/kg H2) from methane, digestate or biogas in an energy-efficient way. Using electricity from renewable sources, methane plasmalysis is just as climate-friendly as electrolysis – but at a much lower cost. That is because it requires only one fifth of the energy compared to water electrolysis. The well-known steam reforming process requires even less energy but produces 9 kg of CO2 per kg of hydrogen.

The Plasmalyzers® are the key to decarbonizing natural gas and biogas because the main component, methane, is not burned, but rather split into hydrogen and elemental carbon.

The hydrogen is then used in hydrogen CHP units, boilers, turbines or SOFC fuel cells for CO2-free heat and power generation

The solid carbon is a valuable auxiliary material for industry and is used for asphalt, concrete, cement or soil improvement, for example. This enables a long-term removal of CO2 from the cycle and is therefore exempt from the CO2 tax.

If biomethane is used and the carbon is permanently bound in products, the process removes up to 11 kg of CO2 from the atmosphere – per kg of hydrogen. Graforce thus offers the first alternative to the controversial CCS storage of CO2 (Carbon Capture Storage) and approaches for a new business model.

In 2020, Graforce was awarded the Innovation Prize of the German gas industry in the efficient energy systems category for emission-free heat generation with a negative CO2 balance.

Would you like to learn more about the many possible applications of plasmalysis in the energy industry? We would be happy to advise you on individual adaptations.