Hydrogen production

Hydrogen holds huge energy potential and is not only found in water. It is a component of many organic and inorganic wastes and residual materials. Graforce has developed a plasma electrolysis process to produce hydrogen from residual materials in an energy-efficient and cost-effective manner.

Graforce does not split water molecules to produce hydrogen, but instead splits nitrogen and hydrocarbon compounds found in wastewater or other feedstocks.

This reduces power consumption and costs. In addition, there are no or even negative CO2 emissions.

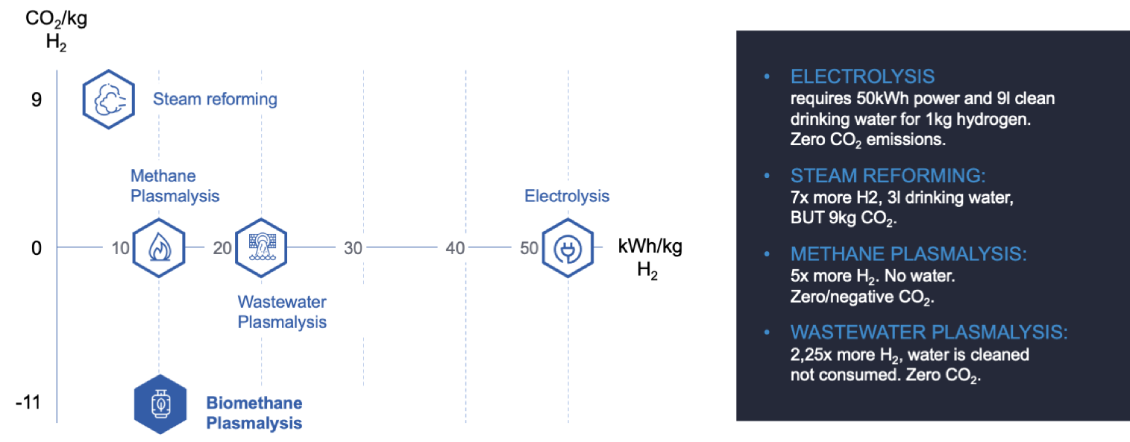

Water is a very stable compound. Therefore previous electrolysis processes require an average of 50kWh of energy to produce 1 kg of hydrogen from distilled water The costs in Germany: 9.00 euros/kg

Sewage water/slurry

20kWh/kg H2

Wastewater, e.g. sludge water from wastewater treatment plants or slurry from biogas plants, contains large amounts of nitrogen and hydrocarbons.

Only about 20kWhof power is sufficient to produce 1 kg of hydrogen from water that contains ammonium using the plasmalysis process. What remains is clean water that can be discharged or reused. More »

Biogas/natural gas

10kWh/kg H2

The hydrogen is bound much weaker in biogas or natural gas. Therefore, 10kWh of energy is already sufficient to extract 1 kg of hydrogen and 3 kg of elemental carbon from 4 kg of biogas or natural gas.

In the decomposition of biogas, the energy production in the hydrogen CHP unit is not only CO2-free, but even possible with a negative CO2 balance. More »

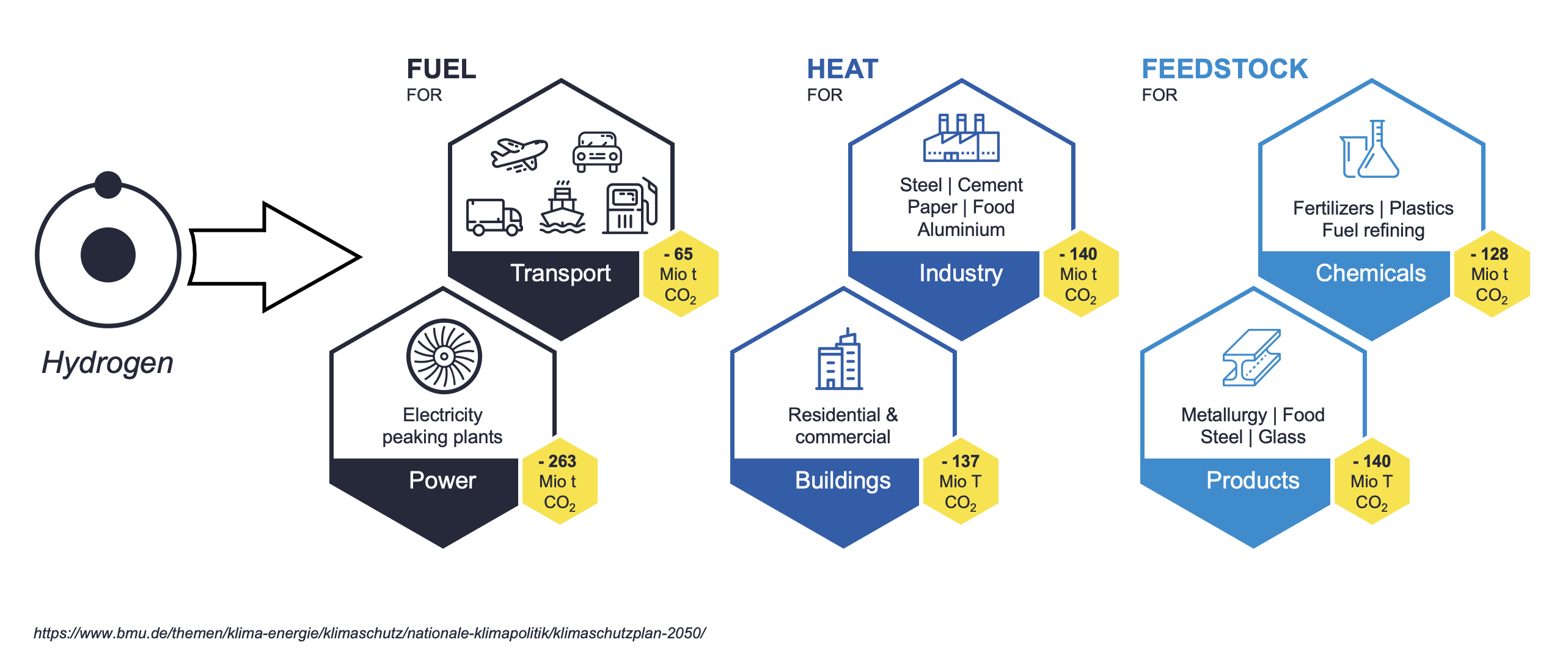

Hydrogen – the key to a CO2-neutral economy

Whether it is used as fuel, heat or raw material – hydrogen can make a significant contribution to achieving CO2 reduction targets in many industries. And it can do so quickly and comparatively inexpensive. The potential is extraordinary.