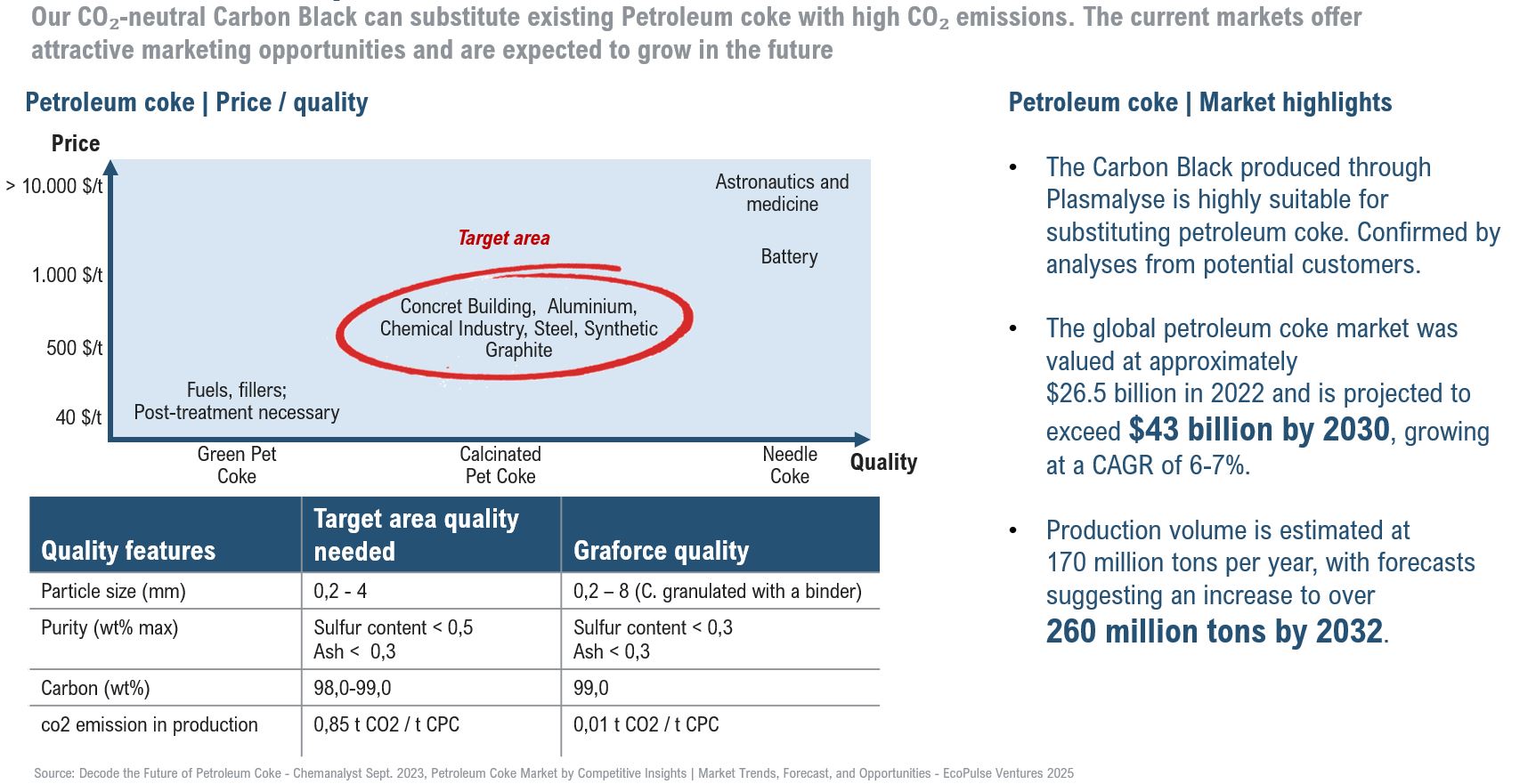

Graforce’s synthetic carbon Our high-purity carbon (99%) is being validated and adopted across a wide range of industries as a sustainable substitute for fossil-based carbon materials. With excellent purity, thermal stability, electrical conductivity, and a low CO₂ footprint, Graforce carbon offers both technical performance and decarbonization potential. It is available at a competitive price of €500 per ton, making it a cost-effective alternative for industrial-scale applications.

Far from being a byproduct challenge, this carbon is a high-value material that enables permanent carbon storage across multiple industrial applications, fully in line with the EU Carbon Removal Certification Framework (CRCF). We focus on use cases that ensure carbon is physically and irreversibly bound for at least 35 years, meeting the CRCF’s highest durability tier for certified carbon removals. Our modular system design and material handling (e.g., carbon silos and transport) support full chain-of-custody documentation and optional third-party verification—ensuring a credible, investable removal pathway.

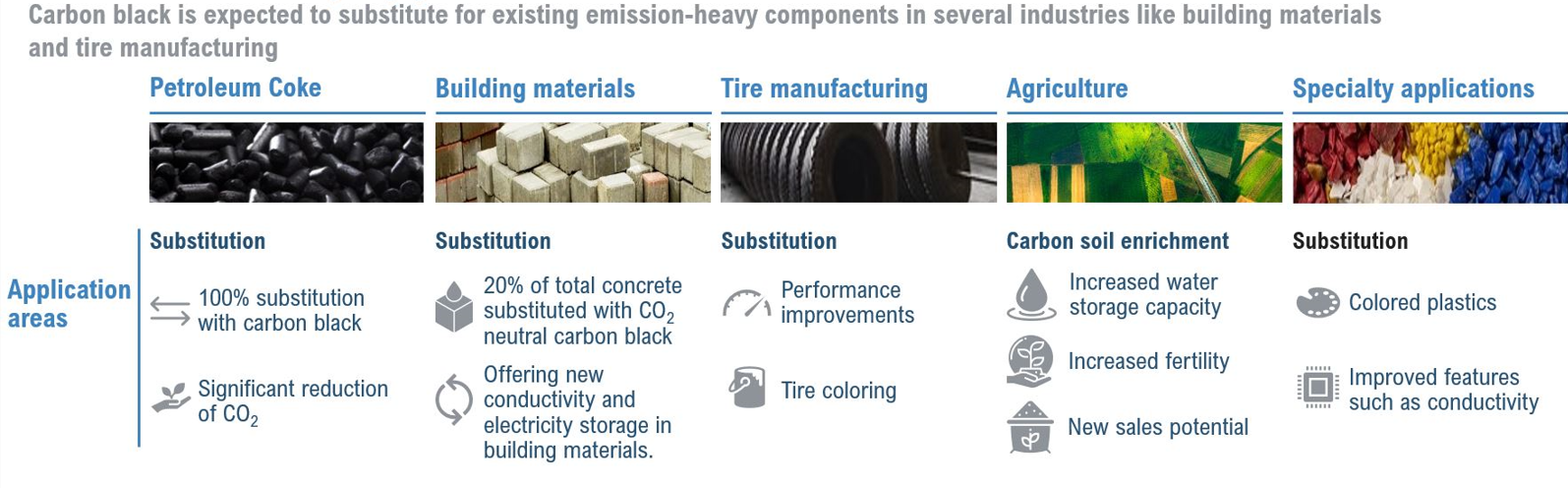

Industrial Applications of Graforce Carbon

Construction Materials

Graforce carbon serves as a functional additive in concrete, asphalt, and cement-based products. In concrete, up to 20% of clinker can be replaced without loss of structural strength—significantly reducing CO₂ emissions. Carbon-enriched concrete can also be made electrically conductive, enabling heated outdoor surfaces such as pavements, ramps, parking areas, and bridges. In asphalt, the carbon can enhance durability and thermal functionality. Once embedded in the concrete matrix, the carbon remains locked for 50+ years, qualifying as permanent storage under the CRCF’s “carbon stored in long-lived products” category.

Steel & Metallurgical Industries

Our carbon is used in steel foundries as a recarburizer and is being explored as a reducing agent in primary metallurgy, offering a cleaner alternative to petroleum coke. Its high fixed-carbon content and extremely low ash make it suitable for iron and steel production processes such as electric arc furnaces and ladle metallurgy.

Refractory Materials & Technical Ceramics

Due to its thermal resistance and structural integrity, Graforce carbon is suitable for high-temperature applications in refractory materials, kiln linings, and technical ceramics. Its low volatility and stable morphology under extreme conditions make it an effective component for long-life, thermally resistant composites.

Specialty Chemicals & Battery Materials

Thanks to its high BET surface area, nanostructured morphology, and conductivity, our carbon is being evaluated for use in energy storage applications (e.g., as a conductive additive in battery electrodes, supercapacitors) and in specialty chemical processes requiring chemically stable, high-surface-area carbons.

Paint & Pigment Industry

In the chloride process for titanium dioxide (TiO₂) production, our carbon is being tested as a sustainable substitute for calcined petroleum coke. Its mechanical strength and particle size distribution are suitable for chlorination reactors, with lower fines and reduced dust formation. It offers a significant CO₂ footprint reduction in pigment production.

Fertilizers & Soil Enhancement

We are developing a carbon-enriched fertilizer that combines nutrient delivery with long-term CO₂ sequestration in soil. The porous structure of the carbon improves water retention and microbial activity, aligning with regenerative agriculture practices.

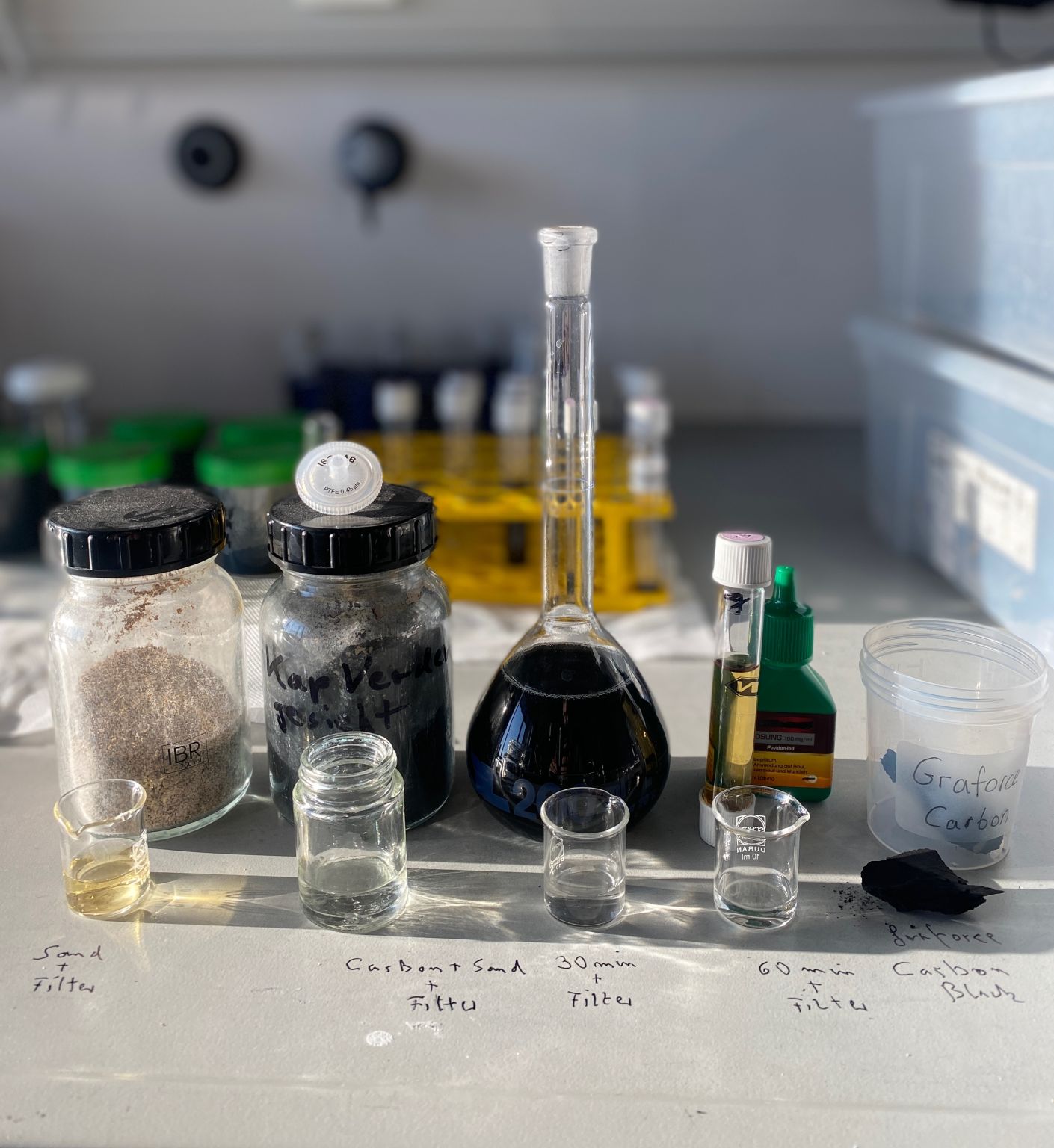

Wastewater Purification

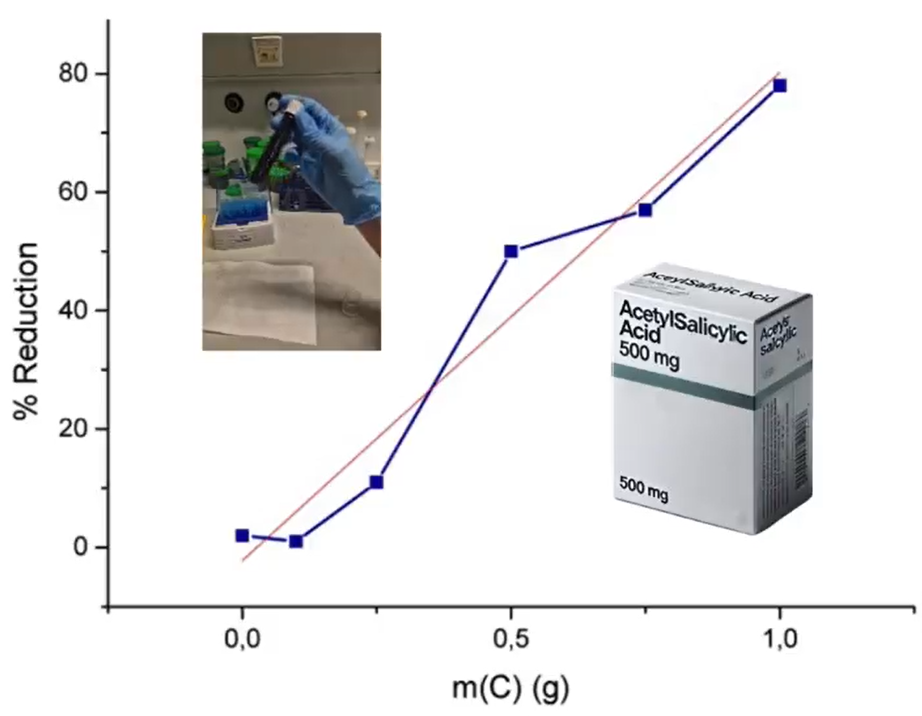

Laboratory tests have demonstrated that Graforce carbon efficiently adsorbs pharmaceutical residues—such as aspirin and povidone-iodine—from water. The removal occurs rapidly, within seconds of simple contact, without the need for elevated temperatures, pressure, or extended reaction times. Due to its large internal surface area, structural stability, and chemical purity, our carbon is a promising alternative to conventional activated carbon in tertiary wastewater treatment. These properties make it particularly attractive for municipal and industrial applications aiming to remove trace contaminants in a cost- and energy-efficient way.

Paint & Pigment Industry

♻️ CO₂ Reduction Potential:

- Up to 80–90% lower CO₂ emissions compared to fossil-derived calcined petroleum coke

- Reduction depends on the carbon intensity of the natural gas source and electricity mix (ideally renewable)

- Long-term carbon storage in durable products (e.g., building materials)

With a projected global market volume exceeding $43 billion by 2030 for calcined petroleum coke, Graforce’s synthetic carbon targets key heavy industries with significant decarbonization potential.

Application Area

Our carbon product targets high-emission applications across steel, pigments, construction, and chemical sectors — enabling deep decarbonization at scale (Multi-Industry Market Potential for Solid Carbon).

Application Area: Construction Materials

Potential Use: Synthetic carbon can be used as a functional additive in cement-based building materials such as concrete, mortar, and asphalt. Particularly promising is the partial substitution of clinker—the most energy- and CO₂-intensive component of concrete—with CO₂-neutral carbon. Pilot applications have demonstrated that up to 20% of the cement content can be replaced without compromising strength or durability.

Additional Benefits:

- CO₂ Reduction: By replacing 20% of Portland cement with solid carbon from methane plasmalysis, every tonne of cement avoids approximately 178 kg of CO₂ emissions (based on 0.89 t CO₂ per tonne of cement), while permanently storing 734 kg of CO₂ in the built environment. This results in a total climate benefit of ~0.91 t CO₂ per tonne of cement used in such concrete mixtures.

-

Thermal and Electrical Storage Capability: Carbon black is conductive and can be used as a component for energy storage within buildings, e.g., for power-to-heat systems or as a thermal battery

-

Long-Term Carbon Storage:The carbon remains embedded in the material for decades, serving as a durable carbon storage or carbon sink (biomethane)

Target Markets: Concrete manufacturers, precast concrete plants, infrastructure projects, cement industry

Application Area: Fertilizers & Soil Enhancement

Potential Use: Synthetic carbon from methane pyrolysis can be applied—depending on quality—as a soil enhancer, similar to biochar. Similarly, 1 million tonnes of carbon used as a soil enhancer (10 t/ha across 100,000 ha) locks 3.67 million tonnes of CO₂ into soils for 100–1,000 years, while reducing fertilizer emissions by ~0.88 million tonnes.

Benefits:

- Water Retention:

Porous carbon black grades can improve the soil’s water-holding capacity, especially in arid regions - Soil Fertility:

Carbon in the soil supports microbial life, retains nutrients, and improves soil structure - Long-Term CO₂ Storage:

Stable carbon in soils can remain for centuries (comparable to Terra Preta) - New Market Segments:

Regenerative agriculture, carbon farming, soil-based CO₂ certificate providers

Application Area: Waste Water purification

Laboratory tests have shown that our carbon removes pharmaceutical residues such as aspirin (acetylsalicylic acid) and vitamin C from water within seconds – without heating, chemical additives, or long contact times. Even gentle shaking is enough to achieve a significant reduction in concentration. Povidone-iodine, a commonly used antiseptic, was also reliably filtered out.

Unlike conventional activated carbon, it is produced under extremely high-energy conditions at around 1500 °C in a hydrogen plasma. During this process, methane (CH₄) is split into its components – hydrogen and solid carbon. The highly reactive hydrogen environment simultaneously activates the carbon directly inside the reactor. The result is an ultrafine, porous, and chemically highly active carbon material with good adsorption performance for industrial and municipal wastewater treatment – regenerable, scalable, and sustainably produced.

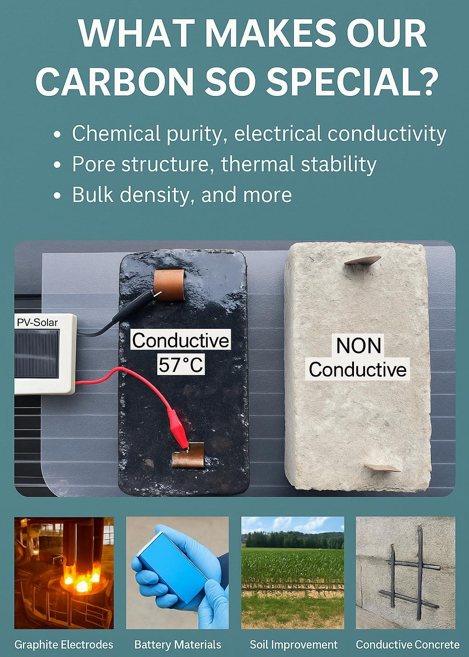

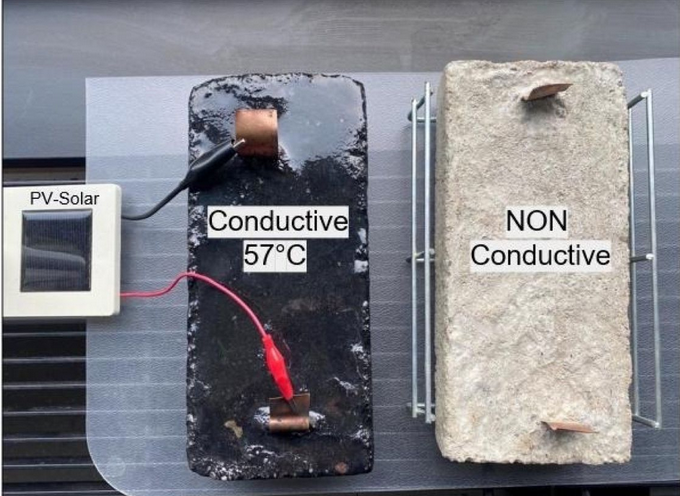

Application Area: Concrete and Conductive

We produce conductive concrete containing up to 15% carbon black derived from our methode.

This advanced concrete offers electrical conductivity, faster curing times, and supports long-term carbon capture, storage, and utilization (CCSU).

Featured on the left is our innovative concrete block next to a standard masonry block on the right.

The carbon in the concrete enables new heating forms for floors, walls, bridges, and parking lots, reducing energy consumption and promoting sustainability.

The integration of a solid-state membrane endows the brick with the ability to store electrical energy and release it as needed. We are eager to find out: What capacity limits can we achieve with this technology.

The Innovation Behind the Process:

In addition to hydrogen, the process creates solid carbon with unique properties that unlock diverse applications, such as:

* Conductive concrete for advanced construction projects

* Energy storage solutions, including large thermal storage systems and hypercapacitors made from cement and carbon

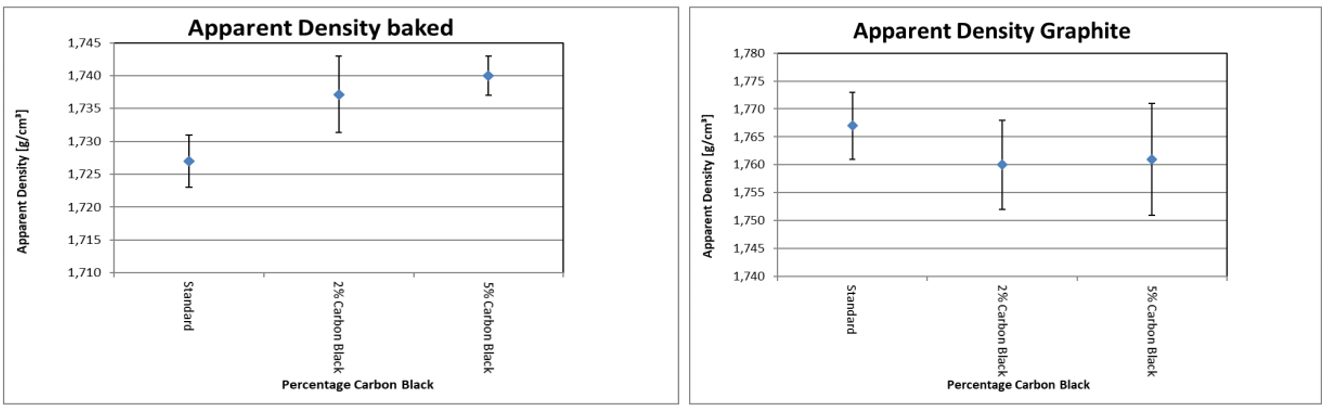

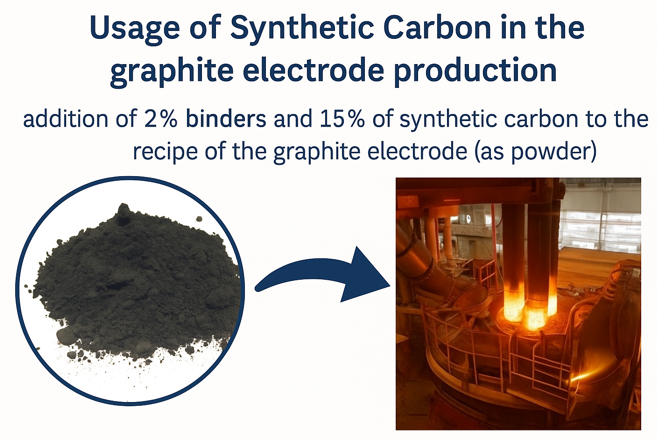

Smart Additives for High-Density Graphite Electrodes

Our synthetic carbon offers an innovative and sustainable substitute material for graphite electrode production. In current trials, the fine powdered carbon was used in typical formulations – with 2% and 5% added to the conventional needle coke base, supplemented by 2% binder. The results show that even small quantities of our material can specifically improve the material structure in the manufacturing process. After baking – i.e. before high-temperature graphitisation – the samples mixed with Graforce carbon exhibit a significantly higher apparent density. The effect is particularly evident with a 5% addition, which achieves a density of around 1.74 g/cm³.

This is above the standard without additives and demonstrates improved packing density and lower porosity in the ‘green’ phase. This compaction behaviour indicates more efficient mould filling and potentially more stable intermediate products. After final graphitisation, the densities of all samples are similar (~1.76 g/cm³). The differences are within the standard deviation range – an important result: the final quality of the graphite electrode is fully retained by the addition of our carbon and corresponds to the level of conventional formulations. Processability is fully retained, while clear optimisation potential arises in the preliminary stage. These investigations show that our plasma-activated carbon is ideally suited as a supplement or partial substitute for fossil-based needle coke. It can be seamlessly integrated into existing manufacturing processes, offers physical advantages in compaction – and at the same time contributes to the decarbonisation of electrode production.

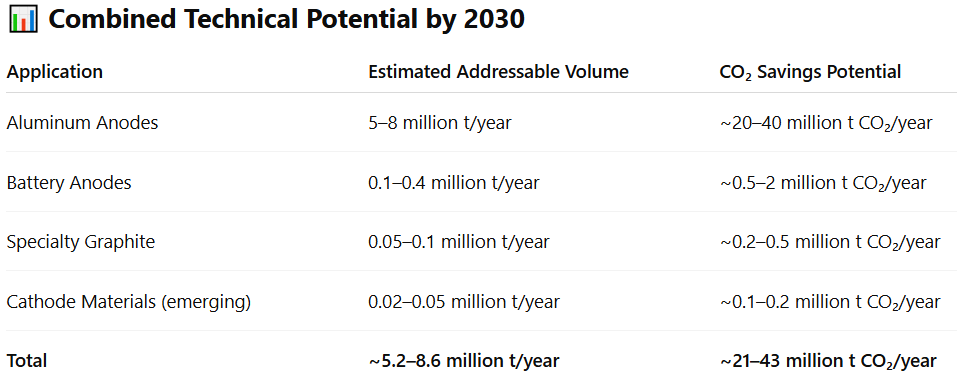

Thanks to its low-CO₂ production process and exceptional purity, our synthetic carbon opens up new perspectives for high-performance applications in the aluminum, battery, and specialty graphite industries.

Anodes for Primary Aluminum Production

In the Hall-Héroult process for aluminum smelting, consumable anodes made from petroleum coke are used. This application demands dense, conductive, and highly pure carbon structures. Our synthetic carbon offers strong substitution potential by partially replacing fossil-based coke—while significantly reducing the carbon footprint of the process.

Anode Materials for Lithium-Ion Batteries

With targeted post-treatment, our carbon can be tailored for battery applications—either as an additive or as a base material for anodes. Its high specific surface area, purity, and chemical stability make it a promising feedstock for next-generation cell technologies, especially for sustainable energy storage systems.

High-Purity Specialty Graphite

Isostatic and fine-grained specialty graphites are widely used in semiconductor, solar, and advanced materials industries. These products require exceptional purity, structural homogeneity, and thermal resistance. Graforce carbon meets these specifications and can serve as a reliable building block for premium synthetic graphite materials.

Emerging Cathode Applications

For novel battery concepts such as dual-ion or sodium-ion systems, conductive carbon is increasingly used as a cathode additive or structural matrix. Our carbon offers a clean, high-performance alternative for these emerging applications.

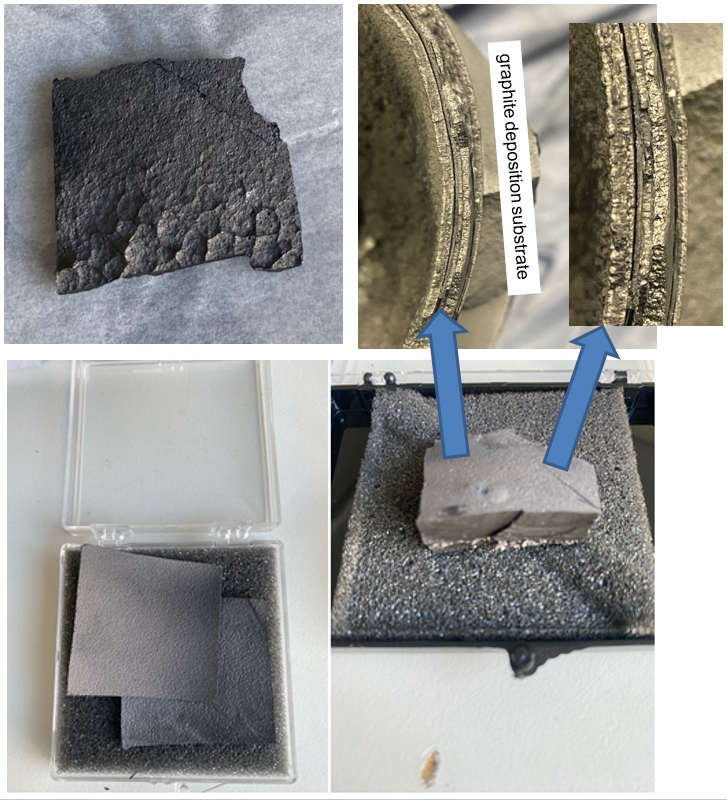

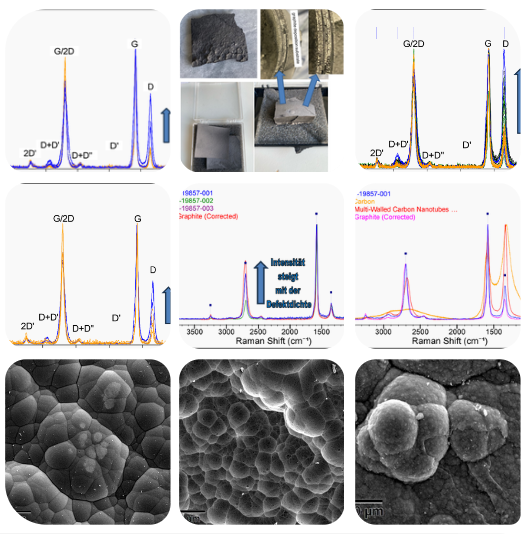

Graphite Formation in Methane Plasmalysis

The deposited carbon produced during methane plasmalysis consists of high-purity, structurally ordered graphite with low defect concentration. The findings highlight:

- Strong potential for in-situ synthesis of technical-grade graphite.

- Applicability in advanced electrode materials, heat storage, or chemically robust carbon components.

- Use as a value-added byproduct for high-performance applications beyond conventional carbon powders.

During methane plasmalysis, graphitic carbon was successfully deposited on a specially integrated reaction surface. The combination of macroscopic observations, SEM imaging, Raman spectroscopy, and XRD analysis confirms the formation of highly ordered, graphitic material with distinct structural and crystalline characteristics.

1. Morphology (SEM Analysis)

The scanning electron microscopy reveals:

- A dense, polycrystalline grain structure, typical of thermally grown graphite.

- Grain sizes ranging from submicron to below 100 µm.

- Uniform, crack-free layers with high surface coverage and mechanical stability.

- A honeycomb-like texture indicative of layer-by-layer graphite growth over local nucleation sites.

2. Raman Spectroscopy

The Raman spectra showed:

- A pronounced G-band (~1580 cm⁻¹), indicating well-ordered sp²-hybridized carbon structures.

- A relatively weak D-band (~1350 cm⁻¹) suggests low structural disorder and high crystallinity.

- A clearly defined 2D-band (~2700 cm⁻¹) characteristic of multilayer or turbostratic graphite.

- A D’/G intensity ratio < 0.3, supporting low defect density.

- An increasing G/2D intensity ratio over time or temperature indicates progressive graphitization.

3. X-ray Diffraction (XRD)

The XRD patterns confirmed:

- Strong peaks around 2θ ≈ 26.5° (002) with additional reflexes—typical for hexagonal graphite.

- Comparison with reference samples (MWCNTs, graphite) shows similar peak distributions.

- Narrow peak widths indicate large crystallite domains and low lattice strain.

4. Macroscopic Sample Observations

The photos displayed:

- Metallic, layered deposits along reactor surfaces.

- Clear carbon layer growth on graphite deposition substrates, as marked by arrows.

- Recovered samples stored in protective cases—flat, cohesive solid discs showing durability and homogeneity.

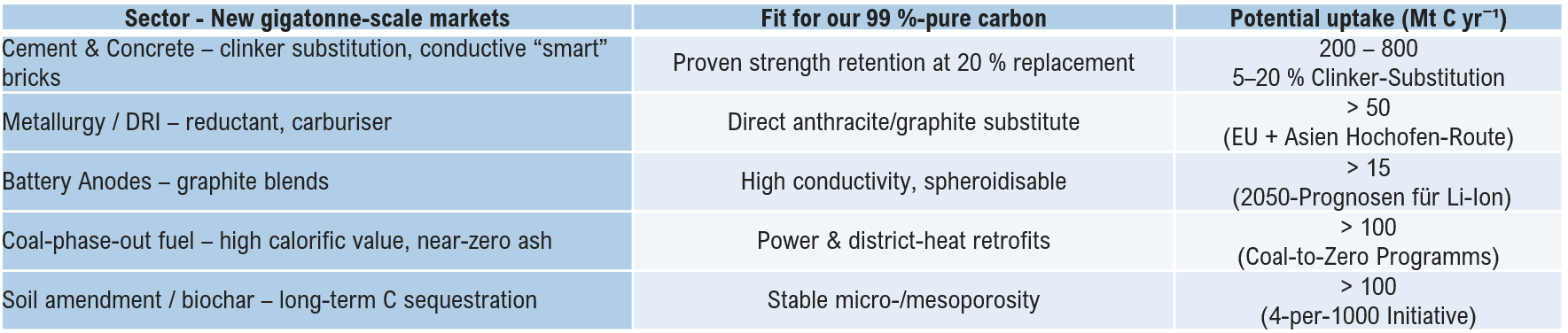

Scaling Carbon Markets for Turquoise Hydrogen – How Graforce Solves the “Carbon Bottleneck”

When would a carbon-volume bottleneck actually hit?

Even in a strong growth scenario, methane pyrolysis would need to cover at least 30–50% of the global hydrogen market before current carbon markets (≈150 million tons per year - carbon black and petcoke) reach capacity. That would correspond to 50–150 million tons of solid carbon annually, which is unlikely before 2040. This gives pyrolysis enough time to scale up new applications that can absorb much larger volumes—something we are already doing.

The table below lists the industrial sectors we are already engaging—each capable of absorbing carbon at gigatonne scale—and indicates their approximate annual uptake potential.

New gigatonne-scale markets we are already opening

Just two of these segments can absorb more carbon than a fully decarbonised hydrogen economy would ever produce